Brief Introduction

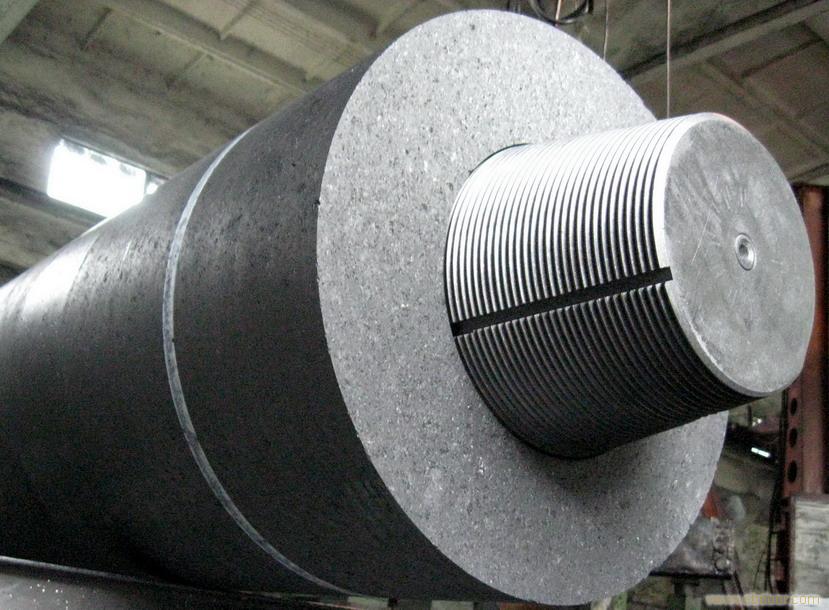

Graphite Electrode

Graphite electrodes are widely used in steel, non-ferrous, silicon and phosphorus melting industry. Good electrical conductivity, high resistance to thermal shock and low oxidation at elevated temperatures.

Our graphite electrode is being carried out with the strict quality control and the products will meet the exacting industrial requirements.

| Properties of Graphite Electrode | ||||||

|

Properties |

Unit |

Nominal Diameter of Electrode | ||||

| HP | UHP | UHP | RP | |||

| 12’’-32’’ | 12’’-24’’ | 26’’-32’’ | 12’’-32’’ | |||

|

Typical Value |

Typical Value |

Typical Value |

Typical Value |

|||

| Resistivity | Electrode | 5.8-6.6 | 4.8-5.8 | 4.6-5.8 | 7.8-8.8 | |

| Nipple | 3.5-4.0 | 3.5-4.0 | 3.5-4.0 | 4.0-4.5 | ||

| Modulus of rupture | Electrode | Mpa | 1.0-13.0 | 10.0-14.0 | 10.0-14.0 | 8.0-10.0 |

| Nipple | 20.0-23.0 | 22.0-26.0 | 22.0-26.0 | 19.0-22.0 | ||

| Young’s Modulus | Electrode | Gpa | 8.0-12.0 | 9.0-13.0 | 10.0-14.0 | 7.0-9.3 |

| Nipple | 14.0-16.0 | 15.0-18.0 | 15.0-18.0 | 12.0-14.0 | ||

| Bulk Density | Electrode | g/cm3 | 1.64-1.68 | 1.70-1.74 | 1.70-1.74 | 1.53-1.56 |

| Nipple | 1.78-1.80 | 1.80-1.84 | 1.80-1.84 | 1.70-1.74 | ||

| CTE(100-600℃) | Electrode |

10-6/℃ |

1.6-1.9 | 1.1-1.4 | 1.1-1.4 | 2.2-2.6 |

| Nipple | 1.1-1.4 | 0.9-1.2 | 0.9-1.2 | 2.0-2.5 | ||

| Ash | % | 0.3 | 0.3 | 0.3 | 0.5 | |

| Note: The figures given above are typical properties for representative products are available | ||||||

| Physical dimension of Electrode | |||||||||||||

| Inch | |||||||||||||

|

Nominial Diameter Inch |

Actual Diameter |

Nominal Length Tolerance | |||||||||||

| 60’’ | 60'' | 72'' | 72'' | 84'' | 84'' | 96'' | 96'' | 110'' | 110'' | ||||

| Max. | Min. |

Min. Crust Diameter |

Standard | Short | Standard | Short | Standard | Short | Standard | Short | Standard | Short | |

| 6’’ | 154 | 149 | 146 | ±100 | -225 | ±100 | -275 | ||||||

| 8’’ | 205 | 197 | 197 | ||||||||||

| 10’’ | 256 | 248 | 248 | ±125 | -275 | ||||||||

| 12’’ | 307 | 299 | 299 | ||||||||||

| 14’’ | 357 | 349 | 349 | ±125 | -275 | ||||||||

| 16’’ | 409 | 400 | 400 | ||||||||||

| 18’’ | 460 | 451 | 451 | -300 | |||||||||

| 20’’ | 511 | 502 | 502 | ||||||||||

| 22’’ | 562 | 553 | 553 | ||||||||||

| 24’’ | 613 | 654 | 604 | +200 | |||||||||

| 26’’ | 663 | 654 | 654 | -150 | |||||||||

| 28’’ | 714 | 705 | 705 | ||||||||||

| 30’’ | 765 | 756 | 756 | ||||||||||

| 32’’ | 716 | 807 | 807 | ||||||||||