Centrifugal and Static Casting Spheroidal Graphite Cast Iron

|

Properties |

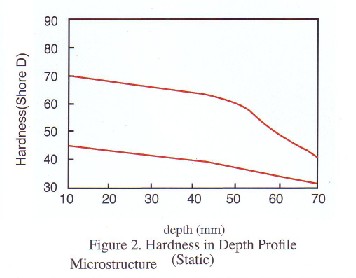

| Thanks to its higher content of Ni and Mo alloys, pearlite, bainite and martensite matrix with excellent performance are produced. The roll has the higher conductivity of thermal and high tensile strength due to the graphite is in spheroidal form. A dense net primary cementite with high wear-resistance is produced through changing the heat treatment technology and the composition of the structure with bainite, martensite and acicular nodular. |

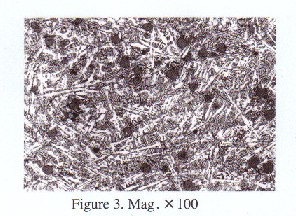

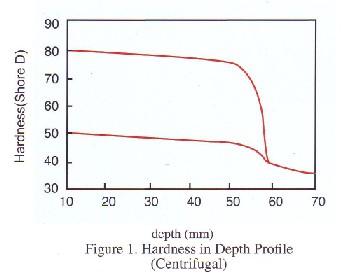

| Mechanical Properties | Centrifugal | Static |

| Hardness of shell | HSD50-80 | HSD45-70 |

| Hardness of neck | HSD35-48 | HSD35-55 |

| Tensile Strength of core | ≥450Mpa | ≥300Mpa |

Chemical Analysis

| Grade | Hardness(HSD) | C | Si | Mn | Ni | Cr | Mo | Mg |

| SGP1 | 50-65 | 2.9/3.4 | 1.2/1.8 | 0.4/1.0 | 0.5/1.0 | 0.2/0.6 | 0.2/0.6 | ≥0.04 |

| SGP2 | 50-70 | 2.9/3.4 | 1.2/1.8 | 0.4/1.0 | 1.0/3.0 | 0.2/1.2 | 0.2/0.6 | ≥0.04 |

| SGP | 60-80 | 3.0/3.5 | 1.2/1.8 | 0.4/1.0 | 3.0/4.5 | 0.2/1.2 | 0.6/1.0 | ≥0.04 |

Applications

Roughing and intermediate stands of various type continuous rolling mill, finishing stands of bar mill, section mill, finishing stands and back up rolls of strip mills, also suitable for stainless-steel strip hot mills.

Prev:Forging Roll

Next:Nothing