Centrifugal Casting High Speed Steel Roll and Ring

|

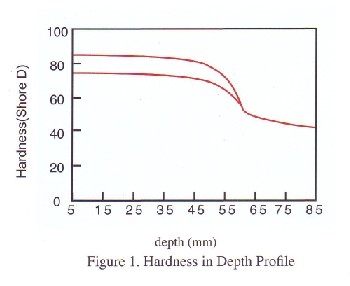

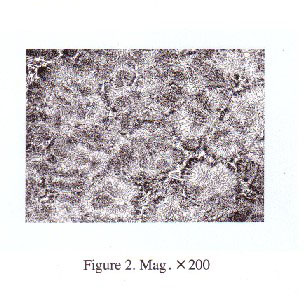

Properties The shell is a high carbon alloy steel containing Cr, Mo, W, V and Nb. The microstructure consists of complex carbides embedded in a tempered martensitic matrix. Control of the carbon and a complex heat treatment allows the optimization of wear-resistance, thermal fatigue resistance and oxide film formation, whilst maintaining low residual stress values.

Chemical Analysis

Applications Widely used as the F5 and F6 work roll for hot strip mills, the pre-finishing stands of high-speed wire mills and the finishing stands of bar mills.

|

|||||||||||||||||||||||||