Brief Introduction

Ramming Paste

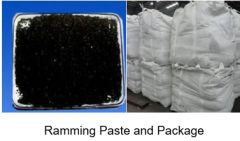

Ramming paste is produced from calcined petroleum coke, calcined anthracite and other binder materials.

Ramming paste is intended for a tamping of seams both between bottom cathode blocks and between sidewall cathode carbon blocks in aluminium reduction cells. It is also used for hearth construction in foundry furnaces as well as iron and steel-making furnaces, and for electric arc furnaces tap hole closing.

| Specification | |||||

| Grade | El.Resistivity | Ash | Compressive Strength | Real Density | Ash |

| μΩ.m | % | Mpa | g/cm3 | % | |

| BSZH | / | 7-11 | 17 | 1.87 | 7 |

| BSTH | 72 | 8-12 | 18 | 1.87 | 7 |

| BSGH | 72 | 9-14 | 25 | 1.89 | 4 |

| GSZH | / | 7-12 | 16 | 1.92 | 5 |

| GSTH | 65 | 8-13 | 16 | 1.92 | 5 |

| GSGH | 65 | 9-14 | 20 | 1.92 | 3 |

| BSLD-1 | / | 9-13 | 18 | 1.87 | 7 |

| BSLD-2 | 72 | 9-13 | 20 | 1.88 | 6 |

| GSLD-1 | / | 9-13 | 16 | 1.89 | 5 |

| GSLD-2 | 65 | 9-13 | 18 | 1.90 | 4 |

Ramming Paste

Ramming Paste